See detailed specifications and technical data for Case TR270 manufactured in 2015 - 2020. Get more in-depth insight with Case TR270 specifications on LECTURA Specs.

Case Tr270 Service Manual Pdf

Case SR130-SR250, SV185/250/300, TR270/320, TV380 Loaders Operators + Service Manuals PDF With Instant Download. Title: epcatalogs.com Case SR130-SR250, SV185/250/300, TR270/320, TV380 Loaders Operators + Service Manuals PDF Created Date: 2/14/2019 10:05:07 PM. Make offer - case tr270 alpha series compact track loader complete repair shop service manual CASE TR320 ALPHA SERIES COMPACT TRACK LOADER COMPLETE REPAIR SHOP SERVICE MANUAL $88.00.

Product Description

Case Tr270 Service Manual Download

Case Tr270 Service Manual Diagram

This product includes Service Manual and Operator's Manual for Case Alpha Series Skid Steer Loaders and Alpha Series Compact Track Loaders.

These manuals include general and safety information, controls and instruments, operating instructions, transport and working operations, maintenance and troubleshooting information, specifications, a lot illustrations, diagrams and schematics.

This product contains PDF manuals, all pages are printable and readable. To view this information you need to install Adobe PDF Reader.

Set includes following PDF Manuals:

- Service Manual - 1738 pages;

- Operator's Manual - 216 pages.

Models covered:

Case Alpha Series Skid Steer Loaders

SR130,

SR150,

SR175,

SR200,

SR220,

SR250,

SV185,

SV250,

SV300.

Case Alpha Series Compact Track Loaders

TR270,

TR320,

TV380.

CONTENTS of Service Manual:

INTRODUCTION

HYDRAULIC, PNEUMATIC, ELECTRICAL, ELECTRONIC SYSTEMS

PRIMARY HYDRAULIC POWER SYSTEM

SECONDARY HYDRAULIC POWER SYSTEM

HYDRAULIC COMMAND SYSTEM

HIGH-FLOW HYDRAULIC POWER SYSTEM

ELECTRICAL POWER SYSTEM

LIGHTING SYSTEM

ELECTRONIC SYSTEM

FAULT CODES

ENGINE AND PTO IN

ENGINE

FUEL AND INJECTION SYSTEM

AIR INTAKE SYSTEM

ENGINE COOLANT SYSTEM

STARTING SYSTEM

TRANSMISSION, DRIVE AND PTO OUT

TRANSMISSION Hydrostatic

AXLES, BRAKES AND STEERING

Final drive

Final drive Hydraulic drive

STEERING Mechanical

PARKING BRAKE Hydraulic

WHEELS AND TRACKS Tracks

WHEELS AND TRACKS Wheels

FRAME AND CAB

FRAME Primary frame

SHIELD

USER CONTROLS AND SEAT

USER CONTROLS AND SEAT Operator seat

USER PLATFORM

ENVIRONMENT CONTROL Heating system

ENVIRONMENT CONTROL Air-conditioning system

SAFETY SECURITY ACCESSORIES Safety

FRAME POSITIONING

STABILISING Ballasting

TOOL POSITIONING

LIFTING

TILTING

LEVELLING

SECONDARY FUNCTIONS Hydraulic

HITCH AND WORKING TOOL

BOOM Lift

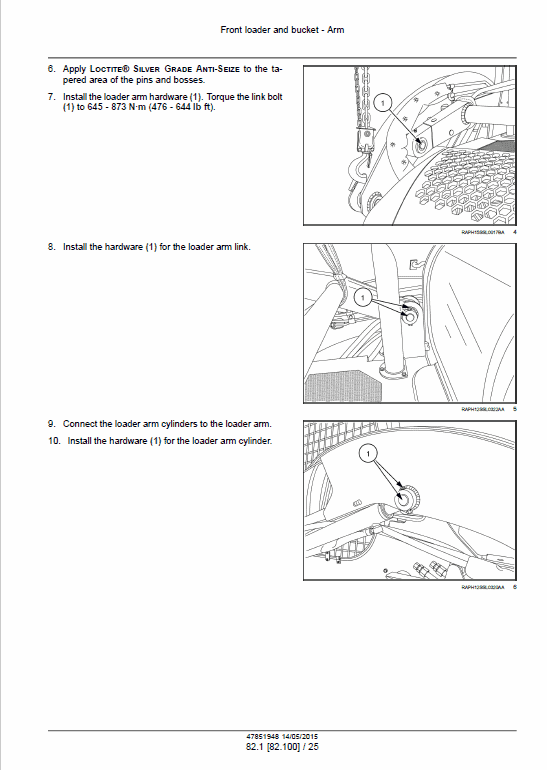

ARM TOOL ATTACHMENT Tilt

SINGLE ARM Lift

SINGLE ARM TOOL ATTACHMENT Tilt

EXCAVATING AND LANDSCAPING

DIGGING Non-articulated digging tools

CARRYING Unarticulated tools

COUPLING Mechanical coupling

COUPLING Hydraulic coupling

Contents of Operator's Manual:

1 GENERAL INFORMATION

Note to the Owner

Right, left, front and rear of the machine

Identification numbers

Machine components

2 SAFETY INFORMATION

Signal word definitions

Safety rules

Decal information

Safety decals

Utility safety

Operator precautions

Proper entry and exit

Starting and stopping precautions

Seat belt precautions

Specific precautions to this machine

Operating precautions

Maintenance precautions

Fuel handling precautions

Burn prevention

Fire extinguisher

California proposition 65 warning

Hazardous chemicals

Transporting precautions

Electro-Magnetic Compatibility (EMC)

Roll Over Protective Structure (ROPS)

Welding on the machine

Mechanical lift arm lock procedure - radial lift machines

Mechanical lift arm lock procedure - vertical lift machines

No engine power - lift arm down control

Emergency exit

3 CONTROLS/INSTRUMENTS

ACCESS TO OPERATOR'S PLATFORM

OPERATOR'S SEAT

MECHANICAL HYDRAULIC CONTROLS

ELECTRO HYDRAULIC CONTROLS

CONTROL HANDLES

AUXILIARY HYDRAULICS

INSTRUMENT CLUSTER

4 OPERATING INSTRUCTIONS

COMMISSIONING THE UNIT

STARTING THE UNIT

STOPPING THE UNIT

MOVING THE UNIT

5 TRANSPORT OPERATIONS

SHIPPING TRANSPORT

RECOVERY TRANSPORT

6 WORKING OPERATIONS

Mechanical attachment mounting systems

Hydraulic attachment mounting systems

Field operation

7 MAINTENANCE

General safety before you service

Lubrication analysis program

Plastic and resin parts

Ecology and the environment

Tilting operator's compartment forward

Machine cleaning

Window removal and cleaning

Cab door removal and installation

Battery safety - check and cleaning

Fire extinguisher

Biodiesel fuel

Engine hourmeter

Wheels and tires

Fluids and lubricants

Lubrication and maintenance access

Fuses and relays

Maintenance Chart

Maintenance procedures

Storage

8 TROUBLESHOOTING

FAULT CODE RESOLUTION

Error code index

9 SPECIFICATIONS

General specification

Material weights

Torque charts - Minimum tightening torques for normal assembly

Units of measure and conversion

Case SR130 Alpha Series Skid Steer Loader

Case SR200 Alpha Series Skid Steer Loader

Case SR150 Alpha Series Skid Steer Loader

Case SR220 Alpha Series Skid Steer Loader

Case SR175 Alpha Series Skid Steer Loader

Case SR250 Alpha Series Skid Steer Loader

Case SV185 Alpha Series Skid Steer Loader

Case SV250 Alpha Series Skid Steer Loader

Case SV300 Alpha Series Skid Steer Loader

Case TR270 Alpha Series Compact Track Loader

Case TR320 Alpha Series Compact Track Loader

Case TV380 Alpha Series Compact Track Loader